Unlocking Precision: How Volumetric Flow Sensing is Revolutionizing Microfluidic Devices in 2025. Explore Market Growth, Breakthrough Technologies, and the Road Ahead.

- Executive Summary: Key Findings and 2025 Highlights

- Market Overview: Defining Volumetric Flow Sensing in Microfluidics

- 2025 Market Size & Growth Forecast (2025–2030): CAGR, Revenue, and Regional Trends

- Drivers & Challenges: What’s Powering and Hindering Adoption?

- Technology Landscape: Current Solutions, Innovations, and Competitive Analysis

- Emerging Applications: Healthcare, Diagnostics, Drug Discovery, and Beyond

- Regulatory Environment and Standards Impacting the Sector

- Competitive Landscape: Key Players, Startups, and Strategic Moves

- Future Outlook: Disruptive Trends, R&D Pipelines, and Market Opportunities

- Conclusion & Strategic Recommendations

- Sources & References

Executive Summary: Key Findings and 2025 Highlights

Volumetric flow sensing in microfluidic devices is a rapidly advancing field, driven by the increasing demand for precise fluid control in applications such as biomedical diagnostics, drug discovery, and chemical analysis. In 2025, the sector is characterized by significant technological innovation, integration with digital platforms, and a growing emphasis on miniaturization and real-time data acquisition.

Key findings for 2025 indicate that the adoption of advanced volumetric flow sensors—such as thermal, Coriolis, and ultrasonic types—has accelerated, enabling higher accuracy and reliability in microfluidic systems. Leading manufacturers, including Sensirion AG and Flusso Ltd, have introduced new sensor models with improved sensitivity, lower power consumption, and enhanced compatibility with a wide range of microfluidic platforms. These innovations are particularly impactful in point-of-care diagnostics, where precise fluid measurement is critical for assay accuracy and reproducibility.

Another highlight is the integration of volumetric flow sensors with Internet of Things (IoT) and cloud-based data management systems. This trend, supported by companies such as ABB Ltd, allows for remote monitoring, predictive maintenance, and seamless data sharing across research and clinical environments. The convergence of microfluidics and digital technologies is expected to streamline workflows and reduce operational costs.

Regulatory bodies, including the U.S. Food and Drug Administration (FDA), have also updated guidelines to address the unique challenges of microfluidic device validation, emphasizing the importance of robust flow measurement for device approval. This regulatory focus is driving manufacturers to prioritize sensor accuracy and traceability in their product development.

Looking ahead, the market is poised for continued growth, with increased investment in research and development, particularly in the areas of wearable diagnostics and lab-on-a-chip systems. The ongoing collaboration between sensor manufacturers, microfluidic device developers, and regulatory agencies is expected to further accelerate innovation and adoption in 2025 and beyond.

Market Overview: Defining Volumetric Flow Sensing in Microfluidics

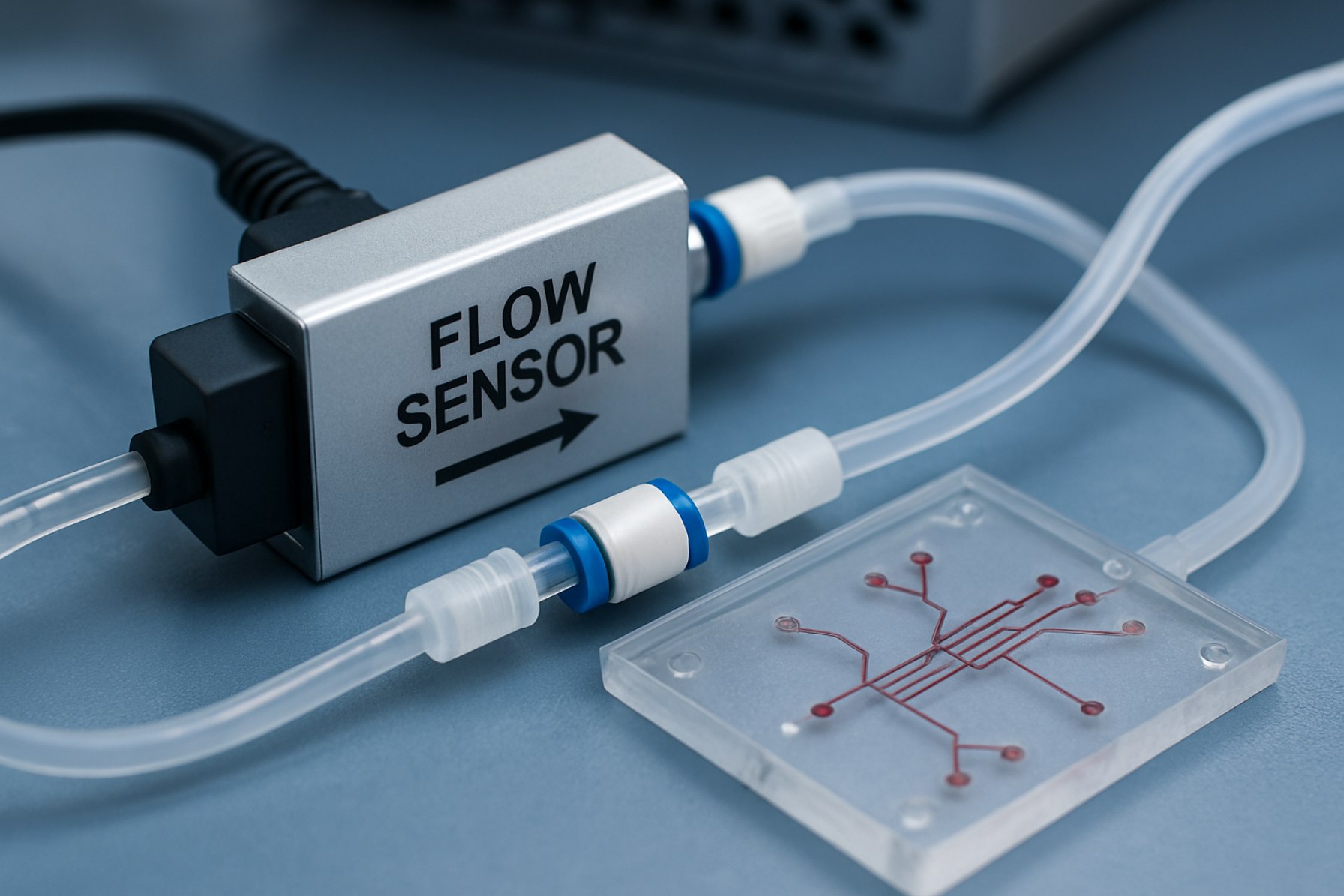

Volumetric flow sensing in microfluidic devices refers to the precise measurement of the volume of fluid passing through micro-scale channels over a given period. This capability is fundamental in microfluidics, where accurate control and monitoring of minute fluid volumes are essential for applications in diagnostics, drug delivery, chemical synthesis, and biological research. Unlike traditional flow measurement techniques, volumetric flow sensing in microfluidics must address unique challenges such as low Reynolds numbers, laminar flow regimes, and the need for non-invasive, real-time monitoring.

The market for volumetric flow sensing in microfluidics has expanded rapidly, driven by the proliferation of point-of-care diagnostics, lab-on-a-chip systems, and the growing demand for automation in life sciences. Key industry players, such as Sensirion AG and Flusso Ltd, have developed specialized microelectromechanical systems (MEMS)-based sensors that offer high sensitivity and integration capabilities suitable for microfluidic platforms. These sensors often utilize thermal, pressure-based, or Coriolis principles to achieve accurate volumetric measurements at the nanoliter to microliter scale.

The integration of volumetric flow sensors into microfluidic devices enables closed-loop control, ensuring reproducibility and reliability in processes such as cell sorting, droplet generation, and reagent mixing. This is particularly important in regulated environments like clinical diagnostics, where precise dosing and sample handling are critical. Organizations such as the Microfluidics Association are actively promoting standardization and best practices to facilitate broader adoption and interoperability of flow sensing technologies.

Looking ahead to 2025, the market is expected to benefit from advances in sensor miniaturization, wireless connectivity, and data analytics, which will further enhance the functionality and accessibility of volumetric flow sensing solutions. The convergence of microfluidics with digital health and personalized medicine is anticipated to create new opportunities for innovation, particularly in decentralized testing and wearable diagnostics. As the field matures, collaboration between sensor manufacturers, device developers, and regulatory bodies will be crucial in addressing technical and regulatory challenges, ensuring that volumetric flow sensing continues to drive progress in microfluidic applications.

2025 Market Size & Growth Forecast (2025–2030): CAGR, Revenue, and Regional Trends

The global market for volumetric flow sensing in microfluidic devices is poised for significant expansion in 2025, driven by advancements in biomedical research, diagnostics, and industrial automation. According to industry projections, the market is expected to achieve a compound annual growth rate (CAGR) of approximately 8–10% from 2025 to 2030, with total revenues surpassing USD 500 million by the end of the forecast period. This growth is underpinned by increasing adoption of microfluidic technologies in point-of-care testing, drug discovery, and environmental monitoring, where precise flow measurement is critical.

Regionally, North America is anticipated to maintain its leadership position, owing to robust investments in healthcare innovation and a strong presence of key industry players such as Fluxergy, Inc. and Thermo Fisher Scientific Inc.. Europe follows closely, supported by government funding for life sciences and a growing ecosystem of microfluidics startups. The Asia-Pacific region is projected to witness the fastest CAGR, fueled by expanding biotechnology sectors in China, Japan, and South Korea, as well as increasing collaborations between academic institutions and industry.

Technological advancements are also shaping market dynamics. The integration of MEMS-based sensors, improved calibration algorithms, and miniaturized electronics are enabling higher accuracy and lower detection limits for volumetric flow sensing. Companies such as Sensirion AG and Innovative Sensor Technology IST AG are at the forefront, introducing new sensor platforms tailored for microfluidic applications. These innovations are expected to accelerate adoption in both established and emerging markets.

In summary, the volumetric flow sensing market for microfluidic devices is set for robust growth through 2030, with regional trends highlighting North American and Asia-Pacific leadership. The sector’s expansion will be propelled by technological innovation, increased R&D spending, and the growing need for precise fluid control in diverse applications ranging from healthcare diagnostics to industrial process monitoring.

Drivers & Challenges: What’s Powering and Hindering Adoption?

The adoption of volumetric flow sensing in microfluidic devices is shaped by a dynamic interplay of technological drivers and persistent challenges. On the driver side, the increasing demand for precision in biomedical diagnostics, drug discovery, and point-of-care testing is a significant catalyst. Microfluidic platforms require accurate, real-time monitoring of fluid flow to ensure reproducibility and reliability of assays, especially as applications expand into personalized medicine and organ-on-chip systems. The miniaturization of sensors and advances in MEMS (Micro-Electro-Mechanical Systems) technology have enabled the integration of highly sensitive volumetric flow sensors directly onto microfluidic chips, reducing system complexity and improving data fidelity. Companies such as Sensirion AG and Honeywell International Inc. are at the forefront, offering compact, high-precision flow sensors tailored for microfluidic applications.

Another driver is the push for automation and high-throughput screening in life sciences and industrial processes. Automated microfluidic systems rely on robust flow control to handle small sample volumes efficiently, and volumetric flow sensors provide the necessary feedback for closed-loop control. Additionally, regulatory requirements for traceability and quality assurance in pharmaceutical and clinical settings are encouraging the adoption of integrated flow sensing solutions.

However, several challenges hinder widespread adoption. One major obstacle is the compatibility of flow sensors with diverse microfluidic materials and fluids. Many microfluidic devices are fabricated from polymers such as PDMS or thermoplastics, which can interact with sensor materials or affect sensor calibration. Ensuring biocompatibility and chemical resistance remains a technical hurdle. Furthermore, the integration of flow sensors can increase device cost and complexity, which is a concern for disposable or single-use microfluidic cartridges.

Another challenge is the need for ultra-low flow detection, as many microfluidic applications operate in the nanoliter or even picoliter per minute range. Achieving high sensitivity without compromising response time or increasing noise is a persistent engineering challenge. Additionally, the miniaturization of sensors must not compromise their robustness or reliability, especially in harsh or variable operating environments.

In summary, while technological advancements and market demands are driving the integration of volumetric flow sensing in microfluidic devices, material compatibility, cost, and technical limitations in sensitivity and robustness continue to pose significant challenges for broader adoption.

Technology Landscape: Current Solutions, Innovations, and Competitive Analysis

The technology landscape for volumetric flow sensing in microfluidic devices has evolved rapidly, driven by the increasing demand for precision in biomedical diagnostics, drug discovery, and chemical analysis. Current solutions predominantly utilize thermal, pressure-based, and optical sensing techniques. Thermal flow sensors, such as those developed by Sensirion AG, leverage the heat transfer properties of fluids to determine flow rates with high sensitivity, making them suitable for low-volume applications. Pressure-based sensors, offered by companies like Honeywell International Inc., measure differential pressure across microchannels to infer volumetric flow, providing robust performance in a variety of fluidic environments.

Optical flow sensing, including particle image velocimetry and laser Doppler velocimetry, is gaining traction for its non-invasive nature and high spatial resolution. Innovations in this area are being spearheaded by research institutions and companies such as Carl Zeiss AG, which integrate advanced microscopy with flow measurement capabilities. Additionally, the integration of MEMS (Micro-Electro-Mechanical Systems) technology has enabled the miniaturization and mass production of flow sensors, enhancing their compatibility with microfluidic platforms.

Recent innovations focus on improving sensor integration, real-time data acquisition, and multi-parameter sensing. For example, Flusso Limited has introduced compact flow sensor chips that can be embedded directly into microfluidic cartridges, enabling point-of-care diagnostics with minimal sample volumes. Furthermore, the adoption of digital calibration and wireless data transmission is streamlining the deployment of these sensors in distributed and automated laboratory settings.

The competitive landscape is characterized by a mix of established sensor manufacturers and emerging startups. Sensirion AG and Honeywell International Inc. maintain significant market share due to their broad product portfolios and global distribution networks. However, niche players like Flusso Limited and Carl Zeiss AG are driving innovation through specialized solutions tailored for microfluidic applications. As the field advances, competition is expected to intensify around sensor miniaturization, integration with digital platforms, and the ability to handle complex biological samples with high accuracy.

Emerging Applications: Healthcare, Diagnostics, Drug Discovery, and Beyond

Volumetric flow sensing in microfluidic devices is rapidly expanding its impact across a range of emerging applications, particularly in healthcare, diagnostics, and drug discovery. The ability to precisely measure and control minute fluid volumes is critical for the reliability and reproducibility of microfluidic assays, which are increasingly used in point-of-care diagnostics, organ-on-chip systems, and high-throughput drug screening platforms.

In healthcare, microfluidic devices equipped with advanced volumetric flow sensors enable the development of portable diagnostic tools that require only microliter-scale samples. These devices can perform complex analyses, such as blood chemistry or pathogen detection, with high sensitivity and specificity. For example, integrated flow sensors help ensure accurate reagent mixing and sample delivery in lab-on-a-chip systems, which are being developed by organizations like Abbott Laboratories and F. Hoffmann-La Roche Ltd for rapid diagnostics.

In the field of drug discovery, volumetric flow sensing is essential for automating and miniaturizing high-throughput screening assays. Microfluidic platforms can generate and manipulate thousands of nanoliter droplets, each serving as an individual reaction vessel. Accurate flow measurement, as provided by sensors from companies such as Sensirion AG, ensures consistent reagent delivery and reliable assay results, accelerating the identification of promising drug candidates.

Beyond traditional biomedical applications, volumetric flow sensing is also enabling innovations in areas such as cell culture, tissue engineering, and environmental monitoring. For instance, organ-on-chip devices, which simulate physiological conditions for tissues and organs, rely on precise flow control to mimic blood flow and nutrient delivery. This is crucial for the development of predictive disease models and personalized medicine approaches, as pursued by research initiatives at institutions like Massachusetts Institute of Technology.

Looking ahead to 2025, the integration of volumetric flow sensors with microfluidic devices is expected to further enhance automation, data quality, and scalability in both research and clinical settings. As sensor technologies become more compact, sensitive, and compatible with a wider range of fluids, their adoption will continue to drive innovation across healthcare, diagnostics, drug discovery, and beyond.

Regulatory Environment and Standards Impacting the Sector

The regulatory environment for volumetric flow sensing in microfluidic devices is shaped by a combination of international standards, regional directives, and application-specific guidelines. As microfluidic technologies are increasingly integrated into critical sectors such as medical diagnostics, pharmaceuticals, and environmental monitoring, compliance with rigorous standards is essential to ensure device safety, accuracy, and interoperability.

In the medical and diagnostic fields, volumetric flow sensors incorporated into microfluidic devices must adhere to regulations set by authorities such as the U.S. Food and Drug Administration (FDA) and the European Commission under the In Vitro Diagnostic Regulation (IVDR). These frameworks require comprehensive validation of sensor performance, including accuracy, repeatability, and biocompatibility, as part of the device’s overall risk assessment and quality management system. The FDA’s 21 CFR Part 820 and the ISO 13485 standard for medical device quality management are particularly relevant, mandating traceability and robust documentation throughout the product lifecycle.

For industrial and research applications, standards from organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) provide guidance on the calibration, testing, and reporting of flow sensor performance. ISO 8655, for example, specifies requirements for piston-operated volumetric apparatus, which can be relevant for certain microfluidic flow measurement systems. Additionally, the IEC 61010 series addresses safety requirements for electrical equipment used in laboratory environments, including microfluidic instrumentation.

Emerging standards are also being developed to address the unique challenges of microfluidic systems, such as the miniaturization of components and the integration of sensors with digital data interfaces. Industry consortia and standardization bodies, including the SEMI (Semiconductor Equipment and Materials International), are working to establish protocols for device interoperability and data exchange, which are critical for the adoption of microfluidic devices in automated and high-throughput settings.

Overall, the regulatory landscape for volumetric flow sensing in microfluidic devices is evolving rapidly, with increasing emphasis on harmonization of standards, digital traceability, and lifecycle management. Manufacturers and developers must stay abreast of these changes to ensure compliance and facilitate market access in 2025 and beyond.

Competitive Landscape: Key Players, Startups, and Strategic Moves

The competitive landscape for volumetric flow sensing in microfluidic devices is characterized by a mix of established instrumentation companies, innovative startups, and strategic collaborations aimed at advancing precision and integration. Leading the market are established players such as Sensirion AG, renowned for its MEMS-based flow sensors tailored for microfluidic and medical applications, and Fluxergy, Inc., which integrates flow sensing into its diagnostic platforms. These companies leverage robust R&D capabilities and global distribution networks to maintain their market positions.

Startups are driving innovation by focusing on miniaturization, cost reduction, and integration with digital platforms. For example, Elveflow specializes in high-precision flow controllers and sensors optimized for microfluidic research, offering plug-and-play solutions that appeal to academic and industrial labs. Similarly, Fluigent has developed a suite of flow control and measurement products, including real-time volumetric flow sensors, that are widely adopted in life sciences and pharmaceutical research.

Strategic moves in the sector include partnerships between sensor manufacturers and microfluidic device developers to enable seamless integration. For instance, Sensirion AG has collaborated with various microfluidics companies to embed its sensors directly into lab-on-a-chip systems, enhancing real-time monitoring and automation. Additionally, companies like Fluigent and Elveflow are expanding their product portfolios through modular systems that combine flow sensing, pressure control, and software analytics, catering to the growing demand for turnkey microfluidic platforms.

The competitive environment is further shaped by the entry of electronics and semiconductor firms exploring MEMS-based flow sensing technologies, as well as academic spin-offs commercializing novel sensing principles such as thermal, Coriolis, and optical methods. This influx of new players is intensifying competition and accelerating the pace of innovation, particularly in applications requiring ultra-low flow detection and high integration density.

Overall, the market for volumetric flow sensing in microfluidics is dynamic, with established leaders consolidating their positions through innovation and partnerships, while startups and new entrants push the boundaries of performance, integration, and affordability.

Future Outlook: Disruptive Trends, R&D Pipelines, and Market Opportunities

The future of volumetric flow sensing in microfluidic devices is poised for significant transformation, driven by disruptive technological trends, robust R&D pipelines, and expanding market opportunities. As microfluidics continues to underpin advancements in diagnostics, drug discovery, and synthetic biology, the demand for precise, real-time volumetric flow measurement is intensifying. Emerging trends include the integration of advanced materials such as graphene and flexible polymers, which enable the fabrication of highly sensitive, miniaturized flow sensors compatible with complex microfluidic architectures. Additionally, the convergence of microfluidics with artificial intelligence and machine learning is facilitating the development of self-calibrating and adaptive flow sensing systems, capable of compensating for environmental fluctuations and device variability.

R&D pipelines are increasingly focused on non-invasive, label-free sensing modalities, such as thermal, capacitive, and optical techniques, which offer high accuracy without interfering with biological samples or reagents. Leading research institutions and industry players are investing in the development of multi-parameter sensors that can simultaneously monitor flow rate, pressure, and temperature, providing comprehensive data for process optimization. For example, Fluxergy, Inc. and Dolomite Microfluidics are actively exploring integrated sensor platforms tailored for point-of-care diagnostics and high-throughput screening applications.

Market opportunities are expanding beyond traditional biomedical and pharmaceutical sectors. The adoption of microfluidic flow sensing is accelerating in environmental monitoring, food safety, and industrial process control, where rapid, low-volume analysis is critical. The rise of personalized medicine and decentralized healthcare is also fueling demand for portable, user-friendly microfluidic devices equipped with reliable volumetric flow sensors. Strategic collaborations between sensor manufacturers, microfluidic chip designers, and end-users are expected to drive innovation and reduce time-to-market for next-generation solutions.

Looking ahead to 2025 and beyond, the sector is likely to witness the commercialization of fully integrated, plug-and-play flow sensing modules, supported by advances in microfabrication and wireless connectivity. Regulatory bodies such as the U.S. Food and Drug Administration are anticipated to play a pivotal role in shaping standards for sensor performance and data integrity, further catalyzing market growth. Overall, the intersection of cutting-edge research, cross-sector collaboration, and evolving application landscapes positions volumetric flow sensing as a cornerstone technology in the future of microfluidics.

Conclusion & Strategic Recommendations

Volumetric flow sensing is a cornerstone technology for the advancement of microfluidic devices, enabling precise control and monitoring of fluid movement at the microscale. As microfluidics continues to expand its applications in diagnostics, drug delivery, and chemical synthesis, the demand for accurate, reliable, and miniaturized flow sensors is set to grow. The integration of advanced volumetric flow sensors enhances device performance, reproducibility, and automation, which are critical for both research and commercial deployment.

Strategically, stakeholders in the microfluidics sector should prioritize the adoption of flow sensing technologies that offer high sensitivity, low power consumption, and compatibility with a range of fluids and device materials. Collaborations with leading sensor manufacturers such as Sensirion AG and Honeywell International Inc. can accelerate the integration of state-of-the-art flow measurement solutions. Furthermore, leveraging open standards and modular sensor designs will facilitate scalability and interoperability across diverse microfluidic platforms.

For research institutions and device developers, investment in the co-development of custom flow sensors tailored to specific microfluidic applications can yield significant competitive advantages. Engaging with organizations like Dolomite Microfluidics and Fluxergy, Inc. can provide access to specialized expertise and prototyping capabilities. Additionally, ongoing collaboration with regulatory bodies such as the U.S. Food and Drug Administration is essential to ensure that new sensing technologies meet evolving standards for safety and efficacy, particularly in clinical and pharmaceutical contexts.

Looking ahead, the convergence of microfluidics with digital health, artificial intelligence, and the Internet of Things (IoT) will further elevate the importance of robust volumetric flow sensing. Strategic investments in sensor miniaturization, wireless connectivity, and data analytics will position companies to capitalize on emerging opportunities in point-of-care diagnostics and personalized medicine. By fostering cross-disciplinary partnerships and maintaining a focus on innovation, the microfluidics industry can continue to drive transformative advances in healthcare, life sciences, and beyond.

Sources & References

- Sensirion AG

- ABB Ltd

- Microfluidics Association

- Fluxergy, Inc.

- Thermo Fisher Scientific Inc.

- Honeywell International Inc.

- Carl Zeiss AG

- F. Hoffmann-La Roche Ltd

- Massachusetts Institute of Technology

- European Commission

- International Organization for Standardization (ISO)

- Elveflow

- Dolomite Microfluidics